Fancy Yarn Twisting Machine

Fancy yarn twisting machine through a complex twisting process, many different types of fiber materials are twisted and combined to form yarns with unique texture, color and appearance. Such yarns are not only visually appealing but also provide a unique tactile experience and are widely used in fashion apparel, home textiles and functional fabrics.

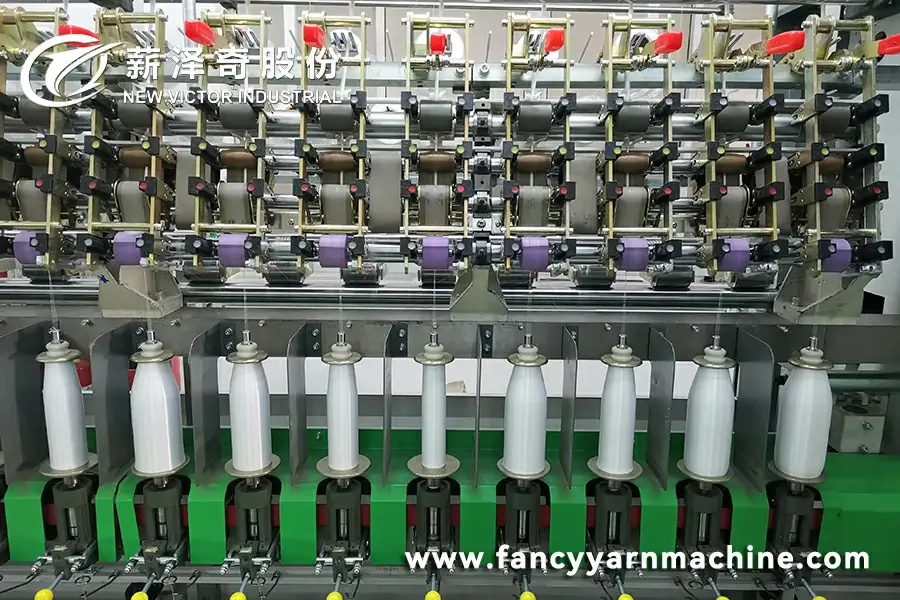

New Victor Industrial has been specializing in the development of fancy twisting machines for more than 20 years, and currently have two models of three-roller fancy twisting machines and four-roller fancy twisting machines.

Three Roller Yarn Twister

Four Roller Yarn Twisting Machine

VFF - 160 Three Rollers Fancy Yarn Twist Machine

Adopting the drafting system composed of rocking frame, the floating thread (floating yarn) is applicable to a wide range; the core thread roller ensures stable yarn molding; the hollow spindle is twisted to form a circle, and the press line ensures the molding.

This machine adopts computerized frequency conversion control, easy to operate, not only facilitates the adjustment of the machine, and makes each way roller infinitely variable speed, thus widening the variation range of spinning fancy yarn, and can randomly set a variety of fancy combination of process parameters.

It is suitable for the production of various kinds of ring yarn, ripple yarn, mohair, potbelly yarn and other fancy yarns. This machine has stable and reliable performance, convenient maintenance, stable yarn quality, low noise and high production efficiency.

Technical Specification of VFF -160 Twisting Machine

MACHINE TYPE | MID - LONG FIBER TYPE | SHORT - MID FIBER TYPE |

|---|---|---|

Operation type | Double face type | Double face type |

Yarn count rang | (Mid - Longer Fiber) 50 ~ 102 mm | (Mid - longer fiber) 38 ~ 65 mm |

Twisting Way | Hollow spindle | Hollow spindle |

Hollow speed | ≤9000 RPM | ≤9000 RPM |

Take - up speed | 6 ~ 28 m/min | 6 ~ 28 m/min |

Spindles | 16 spindle/section Max. 10 sections | 16 spindle/section Max. 10 sections |

Twist run back | Ring winder (Dia. φ112) | Ring winder (Dia. φ112) |

Power rating | 38 KW | 38 KW |

Forming mold | Grooves/winder ( as option) | Grooves/winder ( as option) |

Drafting radio | 1 - 30 | 1 - 30 |

Dia. of drafting roller | φ 38 | φ 30 |

Dia. of core roller | 150 mm | 150 mm |

Twisting direction | S/Z | S/Z |

size | 15400mm*3500mm*2500mm (L*W*H) 160 spindles | 15400mm*3500mm*2500mm (L*W*H) 160 spindles |

This four roller fancy yarn twisting machine is a new type of ultra-fine count fancy twisting machine developed by our company on the basis of widely absorbing the experience of customers and similar models from abroad. It is mainly suitable for spinning medium and high count yarns with high quality and stable pattern. Each roller is driven independently by a dedicated servo motor, which can be adjusted individually or synchronously, making it easy to adjust the process according to the yarn; the lifting and lowering motors are driven by stepping motors with gearboxes, which makes the winding precise, stable and reliable, and is easy to be rewound.

Ring spindle and hollow spindle motors are controlled independently by frequency converter, which can be adjusted individually conveniently and flexibly, and the centralized transmission through the long belt reduces the spindle difference of each spindle and improves the quality of the products.

5 Important Features of Four Roller Fancy Yarn Twisting Machine

1. The speed of each roller and the degree of twisting can be adjusted steplessly, and it is convenient and quick to adjust the process.

2. Ring spindle and hollow spindle are controlled independently by frequency converter, and centralized transmission by long belt reduces the spindle difference of each spindle and improves the quality of products.

3. Mechanical transmission adopts servo motor which is smoother, lower noise and lower breakage rate.

4. Adopting portal rocker, applying force at both ends and being pressurized in the middle, the pressure added on the roller is balanced, and the pressure of the pressurized roller is adjustable at three levels, which can be adjusted very conveniently and flexibly for the different lengths and thicknesses of different raw materials and yarn fibers, which greatly improves the quality of the fancy yarns, reduces the spindle difference of the yarns, and reduces the wastage of the materials

5. The front roller adopts flat groove roller, which makes the spinning yarn more stable and reliable.

Technical Specification of Four Roller Twisting Machine

ITEM | TECHNICAL PARAMETERS |

|---|---|

Quantity of spindles | 8 spindles* section number (max.20 sections) |

Spindle gauge | 150 mm |

Front - rear roller diameter | 45 mm |

Middle roller diameter | 26 mm |

Core roller diameter | 40 mm |

Output roller diameter | 45 mm |

Roller frame | 90° |

Ring diameter | 115 mm/ 90 mm |

Hollow spindle rotate speed | 3000 ~ 9000 RPM |

Direction of twist | S & Z |

Lifting distance | 220 ~ 330 mm |

twist before untwisting | 200 ~ 2000 T/m |

Draft ratio | 1 ~ 50 |

Super feeding ratio | 1:1 ~ 8:1 |

Output line speed | 2 ~ 22 m/min |

Total power (with ring) | 35 kw |

Size | 27400* 2200* 2350 (L*W*H) |

Learn more about fancy yarn twisting machines and discover how you can improve your productivity and product quality. Visit our contact page, where our team of experts is ready to provide you with professional advice and support.