Chenille yarn, because of its plump down, soft hand, thick fabric and light texture, is widely used in the field of home textiles and knitted garments. Chenille decorative products can be made into sofa sets, bedspreads, bed blankets, table blankets, carpets, wall decorations, curtains and other interior decorative accessories. In recent years, it has become a new bright spot in the field of textile new product development and a new growth point for the economic benefits of enterprises. This article will introduce in detail the working principle and application of chenille spinning machine and XXNE-200 type Chenille Machine features.

Working Principle

Chenille Machine is a commonly used equipment in the textile industry for processing fiber raw materials such as cotton and wool into textile yarn. It is based on the principle of stretching, parallel alignment and spinning of fiber raw materials through cross action force and friction, eventually forming a continuous spun yarn.

The main components of a chenille machine are the spinning head and the spinning spindle. The spinning head is the device that is used to provide the spinning yarn, while the spinning spindle is the device that is used to wind and weave the fine yarn. The spinning head contains a component known as the spinning cup, which is a cylindrical container in which the fiber material is placed. Inside the spinning head there is another component called the bottom of the spinning cup, which has a hole through which the fiber material is stretched and injected into the spinning spindle at a specific angle.

The fiber material is first put into the spinning cup, where it undergoes a series of pre-treatments, including cleaning of impurities and stretching, which help to improve the quality of the fiber material and ensure the smoothness of the subsequent spinning operation.

After the fiber in the spinning cup has been pre-treated, it is injected into the spinning spindle. The spinning spindle has a series of spinning holes through which the fibers are stretched and rubbed, gradually forming a textile yarn. During this process, the fibers are subjected to forces that cause them to deflect in the same direction, eventually forming parallel yarns. As the spinning spindle rotates, it also stretches the fibers, making them more uniform and parallel.

The speed at which the spinning machine spindle operates determines the granularity of the spun yarn, i.e. the coarseness or fineness of the fibers. Higher spindle speeds produce fine yarns, while lower spindle speeds produce coarse yarns. The coarseness or fineness of the fibers, in turn, directly affects the output of the spinning machine and the quality of the yarn.

In addition to spindle speed, spinning machines have other control parameters such as pressure control and tension control. Adjustment of these parameters can further improve yarn quality and increase the operating efficiency of the spinning machine.

In short, the chenille machine is a textile device based on the principles of cross action forces and friction. It stretches, parallelizes and spins the fibrous raw material, culminating in a continuous spun yarn. By adjusting a series of parameters, the quality of the yarn can be improved and the productivity of the spinning machine can be increased. For the textile industry, chenille spinning machine is one of the indispensable and important equipment.

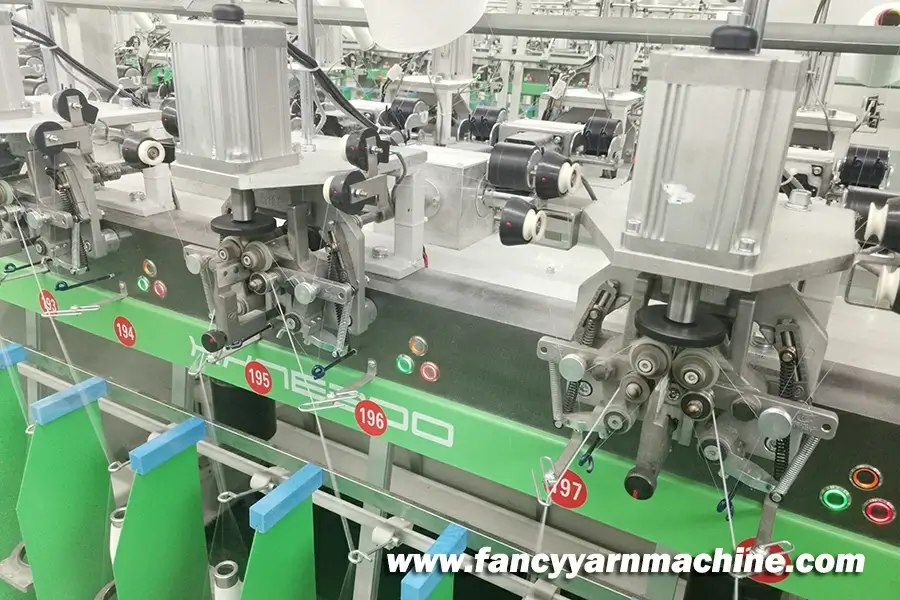

XXNE-200 Chenille Machine

XXNE-200 Chenille Machine is a new high-speed machine developed by our company on the basis of widely absorbing customers’ experience and similar models, which is a double-sided model. This machine is suitable for producing 1-22Nm yarn, characterized by energy saving and high efficiency, eliminating the traditional belt drive structure and adopting servo motor for precise control to reduce transmission loss. Taking 12Nm yarn as an example, the power consumption per ton of yarn is only 2700 degrees.

In addition, XXNE-200 Chenille Machine can save manpower significantly, one blocker can run 300-400 spindles and one mechanic can maintain 2000 spindles. The machine adopts high-tech design, realizing the function of self-stopping yarn breakage and the function of fixed-length yarn drop. In terms of high-end quality, the fine yarn produced by this equipment is of higher quality, effectively solving the problem of flat weaving on circular knitting machines, and the yield rate can reach more than 98%.

Features

①Each rotary head is driven by independent and high speed motor which has steady rotation, low noise and small speed difference. The Max. rotary head can be 24000 rpm, which is two times faster than the old design;

②The rollers are driven by stepper motor to make sure the rotation steadier, the noise lower and the breakage rate lower;

③The high speed spindle is more stable and reliable. The max. speed can be 12000 rpm, which is more than two times faster than the old design;

⑤The lifting movement is driven by stepper motor with precise planetary reducer, to make sure not only the winding more stable and reliable ,but also the unwinding easier;

⑥The rotation of all the rotary heads, rollers and spindles is continuously variable, to make not only the craft adjustment more convenient and faster, but also the shutdown automatic and doffing easier when the bobbin is full;

⑦Spindle distance decreases to 160mm from 200mm,which greatly saves the space and increases the plant utilization

Appliance

Chenille Machine, as a kind of equipment specializing in the production of chenille yarn, plays an important role in the textile industry, with a wide range of applications covering several fields.

- Home textile decorative fabrics: chenille yarn because of its unique soft feel and luxurious appearance, often used in the production of high-grade home textile products, such as pillows, blankets, curtains, bedding sets, etc., to add a sense of warmth and comfort in the home environment.

- Machine knitted garments: In the field of garments, chenille yarn is suitable for making sweaters, scarves, hats, etc. in the fall and winter seasons, providing good warmth and giving clothes a unique texture and style.

- Automotive upholstery: automotive interior decoration, such as seat covers, foot mats, steering wheel covers, etc., also commonly used chenille material, both beautiful and enhance the comfort of the ride.

- Antique fabrics: chenille yarn can imitate the texture of ancient or vintage fabrics, used in the production of antique furniture decorative fabrics, tapestries, etc., to increase the classical flavor.

- Crafts and toys: Using the three-dimensionality and colorfulness of chenille yarn, diverse handicrafts and toys can be created, such as plush toys and decorative hangings.

- Special-purpose fabrics: In some special industries, such as theatrical costumes and holiday decorations, chenille fabrics are favored for their unique visual effects.

- Innovative product development: With the advancement of textile technology, chenille machines are also being used to develop new functional fabrics with properties such as anti-bacterial, anti-static and quick-drying to meet the market demand for high-performance textiles.

To summarize, the application of chenille machine not only enriches the variety of textiles and enhances the aesthetic value and practicality of the products, but also reflects the technological progress and market trends of the textile industry.

Chenille yarn, because of its appearance and shape like a caterpillar-like fancy thread, fluffy, fluffy, soft to the touch, bright colors, with which the texture of the fabric woven into thick and light, is widely used in home textile decorative fabrics, machine knitted garments, automobile decoration supplies and antique fabrics and many other fields.

If you need such Chenille Machine, or want to know more related information, please contact us.

Web: https://www.fancyyarnmachine.com

E-mail: sales@victormac.com