As an important textile equipment, Fancy Yarn Twisting Machine has a wide range of applications in the textile industry. It twists the textile raw material to make the yarn more uniform and stronger, so that it can be used for weaving or knitting into various fabrics. The Traditional Fancy Yarn Twisting Machine belongs to the “ring spindle twisting machine”, which is characterized by the feeder part of the mechanism of the feed yarn movement law with the fancy line requirements and different. Modern Fancy Yarn Twisting Machines are equipped with computers, which can be used to program and control the feeding motion of the feeder section according to the requirements and can produce a variety of different styles and structures of fancy yarns. This article will introduce the process of Fancy Yarn Twisting Machine and the characteristics of XHND-104 Fancy Yarn Twisting Machine in detail.

Fancy Yarn Twisting Machine Process

The process of Fancy Twisting Machine usually includes several processes such as raw material preparation, pretreatment, twisting, adjusting stretching, winding, coiling, etc. The process flow of fancy twisting machine will be described in detail below.

1. Raw Material Preparation

In the production process of fancy twisting machine, the raw materials used are usually chemical fiber, such as polyester, nylon and so on. Before the twisting process, the raw material fibers need to be combed into fiber bundles. In the process of raw material preparation, special attention needs to be paid to the quality and length of the fiber bundle, in order to ensure the smooth running of the subsequent processing process.

2. Pretreatment

After the preparation of raw materials, the fiber bundle needs to be pre-treated, usually through lubrication, carding and other processes, in order to make the fiber bundle more neat, soft, and can be more easily twisted. The pretreatment process needs to be adjusted according to different fiber characteristics to ensure that the final quality of the yarn produced meets the requirements.

3. Twisting

Twisting is one of the core processes of Fancy Twisting Machine. In the process of twisting, it is necessary to rotate the raw fiber bundle through the twisting device for twisting, and in this process, it is necessary to control the twisting degree, twisting direction, twisting fineness and other parameters, so as to make the physical properties of the yarn reach the demand.

4. Adjustment of Stretching

After twisting, it is usually necessary to stretch the yarn in order to make the yarn stronger and more uniform. In the process of adjusting the stretching, according to the equipment characteristics of the spinning machine and product requirements, through the control of the stretching force, speed and other parameters, so that the physical properties of the yarn to get the best adjustment.

5. Winding

After twisting and adjusting the stretching, the yarn needs to be wound on the spinning spindle and curled during the winding process to make the yarn more compact and even. This process usually needs to take into account various factors, such as the balance of the yarn, the control of tension, the way of winding, etc., to ensure the quality of the yarn.

6. Coiling

Coiling: Coiling is the last process of fancy twisting machine, in this process, you need to wind the yarn into rolls for subsequent transportation, storage and use. In the process of winding, according to the product requirements, need to choose the appropriate winding method and winding specifications to meet the needs of users.

The process of fancy twisting machine is a complex systematic project, which requires comprehensive consideration of raw materials, equipment, process parameters and other factors, so as to make the physical properties and appearance quality of yarn reach the best state. By continuously optimizing the process, improving the automation control level of the equipment and perfecting the quality management system, the production efficiency and product quality of the yarn can be effectively improved, so as to obtain better economic benefits and market competitiveness.

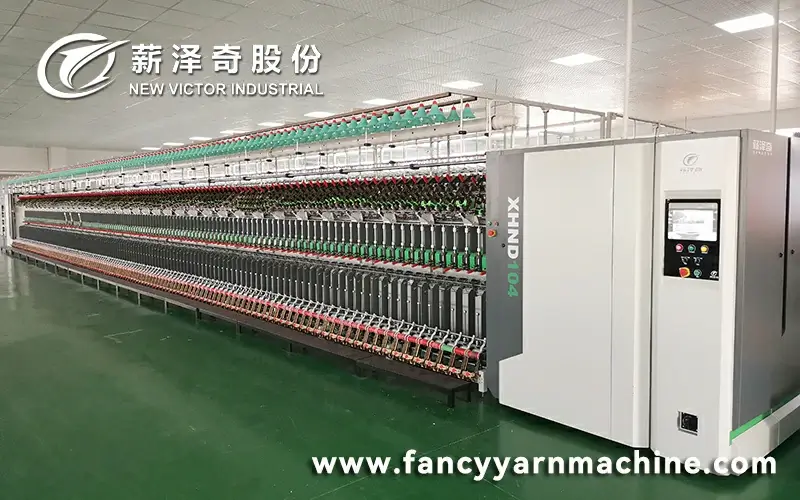

XHND-104 Fancy Yarn Twisting Machine

XHND104 Fancy Yarn Twisting Machine is a new type of ultra-fine count fancy twisting machine developed by our company on the basis of widely absorbing the experience of customers and similar foreign models. It is mainly suitable for spinning medium and high count yarns with high quality and stable pattern.

Each roller is driven independently by a dedicated servo motor, which can be adjusted individually or synchronously, making it easy to adjust the process according to the yarn; the lifting and lowering motors are driven by stepping motors with gearboxes, which makes the winding precise, stable and reliable, and is easy to be rewound. Ring spindle and hollow spindle motors are controlled independently by frequency converter, which can be adjusted individually conveniently and flexibly, and the centralized transmission through the long belt reduces the spindle difference of each spindle and improves the quality of the products.

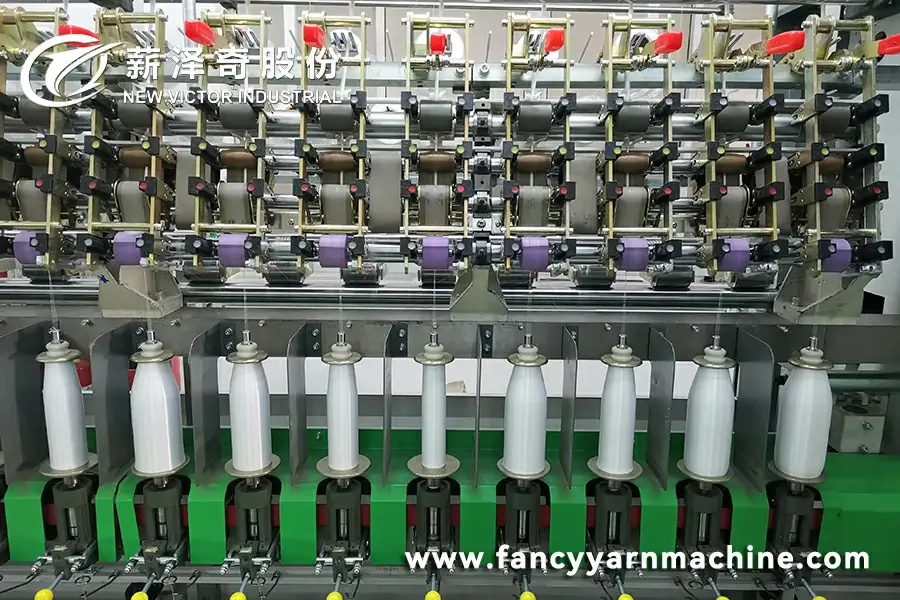

It has the following characteristics:

- The speed and untwisting twist of each roller can be step-less adjusted to ensure the process adjustments convenient and quick.

- The ring spindles and hollow spindles are all controlled by independent inverters, transmitted by a long belt, which decreases the spindle difference and improves the products quality.

- Adopting the servo motor to keep operation smooth with lower noise and finished yarn with lower breaking rate.

- The portal frame exerts force on the two ends and is put pressure on the middle, which ensures on rollers is balanced. And the forcing roller is 3-level adjustable. Through these, even if the raw material and yarn fibers are totally different in the length and thickness, it makes the adjustment flexible, improves the yarn quality, decreases the spindle difference and reduces the raw material waste.

- Adopting slotted roller ensures stable and reliable in the yarn forming process.

After exploring the delicate process and innovative technology of the Fancy Yarn Twisting Machine, we are deeply impressed by the profound impact that this masterpiece of the industry has had on the textile industry. By combining traditional techniques with modern technology, our fancy yarn twisting machines not only increase productivity, but also guarantee superior yarn quality.

If you are interested in Fancy Yarn Twisting Machines, Please contact us.

Web: https://www.fancyyarnmachine.com

Email: sales@victormac.com